Answer:

The capacity of the lathe department is 3200 parts/week. The workers capacity is the bottleneck.

Step-by-step explanation:

In this case we have to compare the machine capacity and the worker capacity, and detecting shich one is limitating the capacity of the department.

Machine capacity

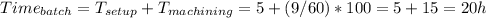

The time it takes for a machine to process a batch is

In 40-hour week, every machine can process 2 batches/week.

With 20 machines, the capacity of the department is 2*20=40 batch/week (4000 pcs/week).

Workers capacity

With 40-hour week and 5-hours setup, every worker can make (40/5)=8 setups a week.

If the department has 4 workers, the amount of setups that can be done is 4*8=32 setups/week. That means that only 32 batches can be processed per week (3200 pcs/week).

The workers resource is the limitating capacity, and therefore the capacity of the lathe department.