Answer:

We know that

For specimen in compression we have engineering strain is -1.5 which is not possible since a item cannot compress more than it's initial length

2)

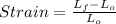

For item in tension we have

3) the true strain are obtained when we use the actual area of the specimen in calculating stress in the specimen which decreases due to poission effect and necking and not the initial nominal area. The true strain is related to engineering strain as

Applying values

For specimen in tension we have