Answer:

The best order size to minimize cost will be 5,000

They will produce for 10 days in a row.

Step-by-step explanation:

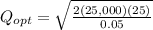

D = annual demand 25,000

S= setup cost = ordering cost 25

H= Holding Cost = 0.05

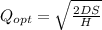

EOQ = 5,000

EDIT: there is insufficient information to solve the third question as the previous scenario wasn't attached.