Answer:

The minimum sample size required is 3385.

Explanation:

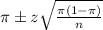

In a sample with a number n of people surveyed with a probability of a success of

, and a confidence level of

, and a confidence level of

, we have the following confidence interval of proportions.

, we have the following confidence interval of proportions.

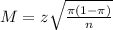

In which

z is the zscore that has a pvalue of

.

.

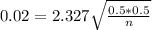

The margin of error is:

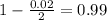

98% confidence level

So

, z is the value of Z that has a pvalue of

, z is the value of Z that has a pvalue of

, so

, so

.

.

To estimate the proportion within 0.02 and with 98% confidence, what is the minimum required sample size if the company currently has no idea about the

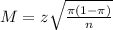

The minimum sample size required is n.

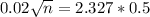

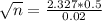

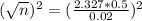

We find n when

We don't know the true proportion, so we use

, which is when the largest minimum sample size will be needed.

, which is when the largest minimum sample size will be needed.

Rounding up

The minimum sample size required is 3385.