Answer:

The optimum production quantity is 72 wheel bearings per batch.

Step-by-step explanation:

Wheel Rite can produce 480 wheel bearings per day.

Setup cost are $39 per batch.

Holding costs are $0.70 per unit per year.

The optimum batch size can be calculated as the one that minimizes the cost. This can be calculated with the Economic Order Quantity formula:

In this case, the units are:

D: daily demand (52 u.)

S: Setup cost per order ($39)

H: holding cost per unit per year ($0.70)

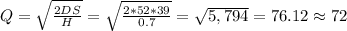

Then, we have:

The optimum production quantity is 72 per batch.