Answer:

a. The scatter diagram created with he given data is attached

b. The scatter diagram indicates that the Number of Defective Parts found increases with Line Speed

c. The regression model is Y = 27.5 - 0.3·X

When the line speed is 25 feet per minute, the number of expected defective parts is 20 defective parts

Explanation:

The give data is presented as follows'

Line Speed;

20, 20, 30, 30, 40, 40, 50, 50

20, 20, 30, 30, 40, 40, 50, 50

Number of Defective;

23, 21, 19, 16, 15, 17, 14, 11

23, 21, 19, 16, 15, 17, 14, 11

Parts Found

a. Please find attached the scatter diagram created with Microsoft Excel

b. From the scatter diagram there is an apparent correlation between increase line speed and the number of defective parts found

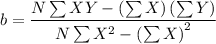

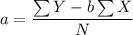

c. The equation for linear regression by the least squares method is presented as follows;

Y = a + b·X

Where;

From Microsoft Excel, we have;

∑X = 280, ∑Y = 136, ∑X² = 10,800, ∑XY = 4,460, (∑X)² = 78,400, N = 8

Plugging in the values, we get;

b = (8×4,460 - 280×136)/(8×10,800 - 78,400) = -0.3

a = (136 - (-0.3)×280)/8 = 27.5

Therefore, we have the linear regression as follows;

Y = 27.5 - 0.3·X

Therefore, when the line speed is 25 feet per minute, we have;

Y = 27.5 - 0.3 × 25 = 20

The number of defective parts expected to be found when the line speed is 25 feet per minute, Y = 20 defective parts.