Answer:

1,082

Explanation:

The sample size n in Simple Random Sampling is given by

where

z = 1.645 is the critical value for a 90% confidence level (*)

s = 2 is the estimated population standard deviation

e = 0.1 mm points is the margin of error

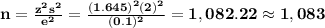

so

rounded up to the nearest integer.

So the manufacturer should test 1,083 parts.

---------------------------------------------------------------------------------------

(*)This is a point z such that the area under the Normal curve N(0,1) outside the interval [-z, z] equals 10% = 0.1

It can be obtained in Excel with

NORMINV(1-0.05,0,1)

and in OpenOffice Calc with

NORMINV(1-0.05;0;1)